Beam Layout Welding Paper

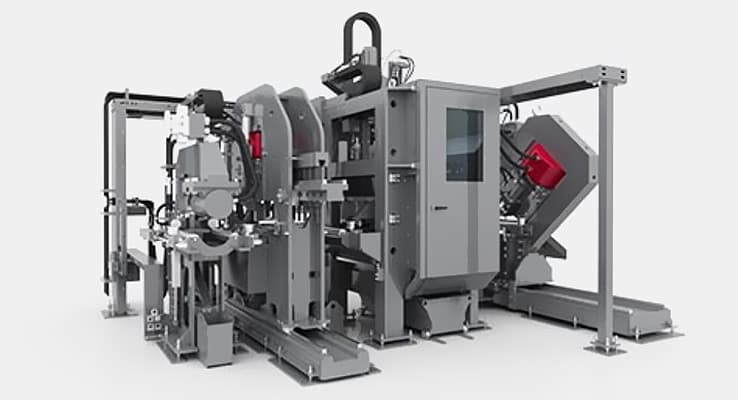

Beam Layout Welding makes it possible to join web sections together with a 100% welded seam. The edges of the two pieces are used as guides and the air cylinders clamp them in place. The grooved copper backup plate is placed against the lower end of the joint. The welding head follows the joint and welds by a single-wire, submergedarc.